Dynamic Testing

Dynamic tests involve subjecting samples to varying conditions to simulate real-world scenarios. Vibration and shock tests evaluate a product's durability under mechanical stress. Vibration tests simulate conditions like transportation or machinery operation, while shock tests assess a product's ability to withstand sudden impacts. These dynamic tests help identify weaknesses, ensuring products meet quality and reliability standards before reaching the market.

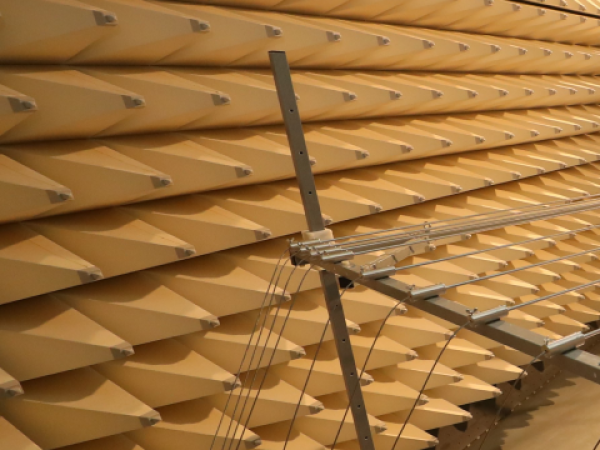

Vibration Testing

We conduct vibration tests to assess product performance and stability under dynamic conditions. This helps ensure quality, durability, and compliance with standards.

Shock Testing

Shock testing involves subjecting a product or sample to sudden and intense impacts to assess its ability to withstand such forces. This type of testing helps identify potential weaknesses and ensures that products can endure unexpected shocks during transportation, handling, or usage.

Combined Testing (Dynamic and Climatic)

Products face multiple challenges, including exposure to simultaneous vibration and shock. Therefore, we simulate these anticipated conditions to evaluate the products' ability to withstand and operate effectively and reliably.